FACTORY ・ PRODUCTION EQUIPMENT

To improve our customer’s competitiveness, our production technical team is continuously making improvement on QCD.

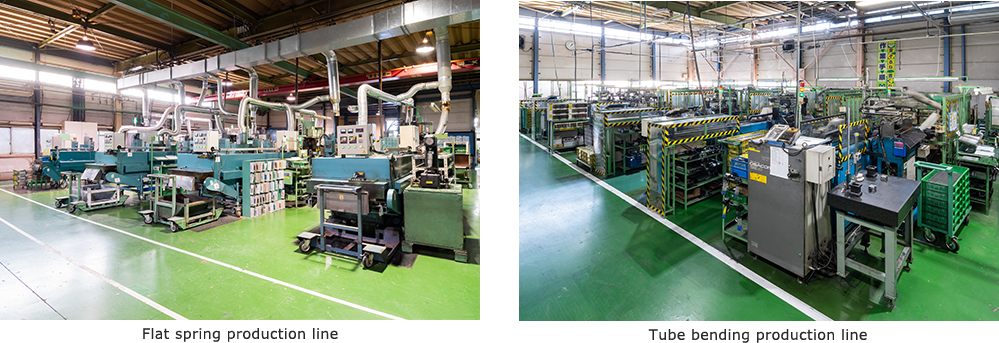

Our production technical skills in Hirata factory

Group’s headquarter factory

Hirata factory was our main factory founded in 1991, the environment where the factory located is really good and suitable for living. The automatic technology and equipment has been integrated as a whole since 1970. As our headquarter factory, it undertakes all the production lines’ design for China factory and continues on the innovation.

From curly equipment to combined production line

We develop different products independently and adopt suited production line.

It’s obvious that we can’t meet all technical requirements if we only stayed on current equipment combination. Our company has been working on the development of CNC equipment and different customized production lines since 1983. From the single curly equipment to various combined production line, our creative skills are embodied through each part, each tooling and equipment.

Ideas got on-the -spot and realize the reasonable engineering design

Self-produced equipment developed by technicians with intelligence and persistence.

In our Hirata factory, everywhere you see is full of the painstaking efforts and wisdom of our workers. For example, you may see the creativity on moving different complicated semi-products, small-scale production line integrated with special processes, full use of image recognition technology to do auto-check etc. Our aim is to improve single equipment speed and analyze the whole engineering to find potential problems. Then, there is no waste and rationalization is realized maximally.

Reliable quality management

Build the quality management and insurance system with newest instruments and manpower.

Quality management is not only the judgement for one product, but also the reflection of company brand.

Be aware of this, our company is very strict with inspection process and we are striving for eliminating defective products by using newest inspection instruments.

Besides, we share our technology with our overseas companies to organize a group quality management system.

However, no matter how the automatic equipment is developed, we still trust that our workers’ self-ability and rich experiences are more reliable.

To make a big improvement on our quality, we bring in newest instruments and also apply our technicians’ intelligence into practice.

Be aware of this, our company is very strict with inspection process and we are striving for eliminating defective products by using newest inspection instruments.

Besides, we share our technology with our overseas companies to organize a group quality management system.

However, no matter how the automatic equipment is developed, we still trust that our workers’ self-ability and rich experiences are more reliable.

To make a big improvement on our quality, we bring in newest instruments and also apply our technicians’ intelligence into practice.

Authentication (HEAD OFFICE/HIRATA FACTORY)

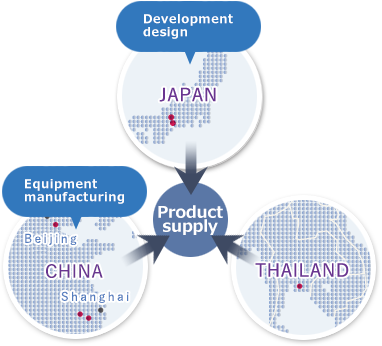

Group development expands business to global

Japanese base is in charge of design & development, China base is responsible for hardware processing and supply products to Japan・ China ・Thailand.

Make flexible use of our overseas bases is our advantage.

Japan base is responsible for new product’s design & new technology’s development. China base is responsible for the manufacturing of molding & equipment and providing the equipment to Japan ・ China ・ Thailand.

Japan, China and Thailand work together to build a group development system and provide the products with new technology which can be commonly used worldwide.

Japan base is responsible for new product’s design & new technology’s development. China base is responsible for the manufacturing of molding & equipment and providing the equipment to Japan ・ China ・ Thailand.

Japan, China and Thailand work together to build a group development system and provide the products with new technology which can be commonly used worldwide.